From Poo to Power – new call for potential of poo power to be explored as source of renewable energy

- Arla’s 460,000 cows could provide enough power each year to fuel over 1.2m UK homes

- A single Arla cow’s yearly poo could power three households per year

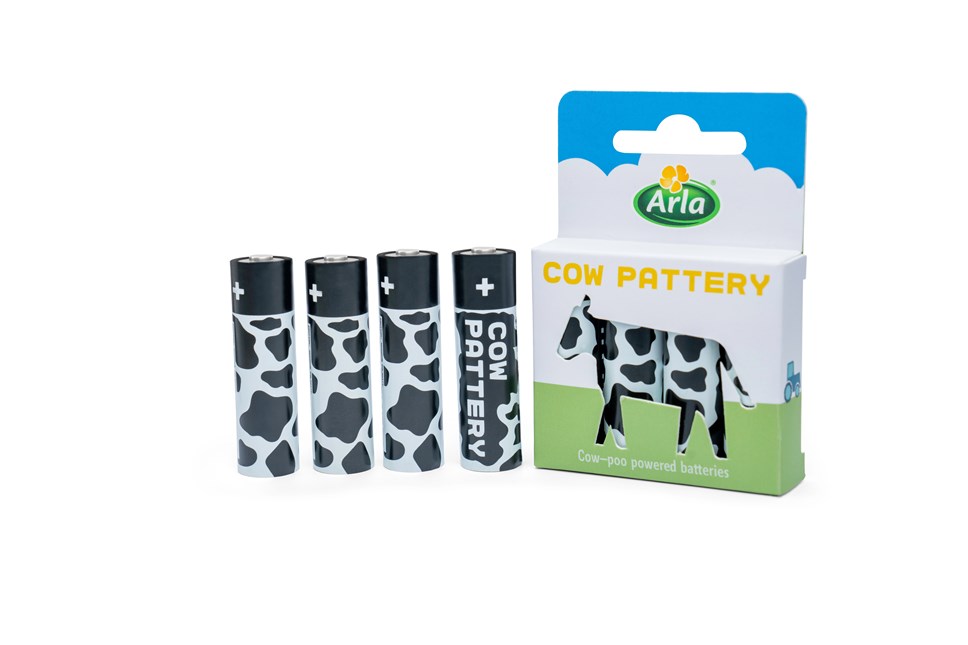

- Dairy cooperative releases ‘cow poo powered patteries’ to highlight the untapped potential across Britain’s dairy farms to help drive the nation towards renewable energy targets

The recent gas crisis has seen worldwide wholesale prices soar, leading to concerns and questions about the cost and source of future supplies. This has highlighted the need to find additional sources of power that are both sustainable and reliable.

A group of farmers from dairy cooperative, Arla, are now showing the largely untapped potential of waste by turning cow poo into cow power to run their farms. To showcase the possibilities this has for us all, Arla has created AA rechargeable ‘Cow Patteries’, which could be one part of Britain’s renewable energy solution.

The focus on renewable energy sources has historically centred on wind and solar, but in a bid to effectively use all resources available, the scale up of anaerobic digestion sites across the UK could provide new opportunities to power homes and transport across the country. Cow slurry is consistent and reliable and has the potential to play a very real part in how we collectively reach our net zero targets by turning it into a source of green gas.

The process also has the additional benefit of generating a by-product that can be used as a natural fertiliser enabling farmers to enrich the land and close the loop on their farm. With over 1.2m tonnes of cow slurry available in the UK each year from Arla’s 2,240 farms alone, the farmer-owned cooperative could generate enough green energy to power four per cent of UK households.

Arla farmer, Neil Ridgway explains “There is so much potential for innovations such as anaerobic digestion to contribute to the UK’s renewable energy needs whilst reducing farm emissions with something readily available on our farms – poo! On my farm, we already use the energy produced from cow slurry to power our entire estate, but this could go so much further. We are even able to use the by-product of the process as a natural fertiliser on our land and thereby closing the loop – it’s a win-win situation!”

Anaerobic digestion is the process used to turn cow slurry into energy. During the process, organic matter such as animal waste is broken down to produce biogas and bio-fertiliser. This process happens in the absence of oxygen in a sealed, oxygen-free tank called an anaerobic digester. The end product is biogas. Once the biogas is cleaned, it is taken to a Combined Heat and Power (CHP) unit, where it is used to generate renewable energy. The end product is nutrient-rich, reduced-emission, natural fertiliser, that can be put back on the land to help nourish the soil.

Graham Wilkinson, Group Agriculture Director at Arla, adds, “Arla is committed to sustainable farming and reducing emissions from food production. Our farmers are constantly exploring innovative solutions and following our poo-powered transport trials last year, it’s clear we have only just scratched the surface. Arla farms are home to around 460,000 cows that provide a steady source of slurry – in other words poo, that can be turned into power that has the potential to make a considerable contribution to Britain’s renewable energy quota. A small number of our farmer-owners are already turning cow poo into energy. If the Government and the energy industry could see the potential, the scaling up of cow power could be a game-changer for the UK’s renewable energy supply whilst also helping reduce emissions in farming.”

Neil Ridgway concluded, “My farm already produces enough cow poo power to keep the lights on across my business and the local community, helping us on our way to becoming carbon net zero. I’d love to be buying cow patteries in the future as they really highlight the potential in this natural resource! With the right support and infrastructure maybe we could turn that possibility into reality.”

ENDS

To find out more about Arla’s renewable energy initiatives, visit the Arla website www.arlafoods.co.uk

Contact Information

Elizabeth Newton

07980 948159

elizabeth.newton@arlafoods.com

For all media enquiries please contact the press office on 07980 948159.